Top 10 Innovations in the LNG Industry

The Liquefied Natural Gas (LNG) industry has seen significant advancements in recent years, driven by the need for cleaner energy sources and more efficient technologies. Here, we explore the top 10 innovations that are transforming the LNG sector, enhancing its efficiency, sustainability, and profitability.

1. Floating LNG (FLNG) Facilities

FLNG facilities have revolutionized the way natural gas is processed and liquefied. These floating units can operate offshore, directly above gas fields, eliminating the need for long-distance pipelines to onshore facilities. This innovation reduces environmental impact and lowers production costs.

2. Small-Scale LNG Plants

Small-scale LNG plants are designed to produce LNG in smaller quantities, catering to niche markets and remote areas. These plants provide flexibility in LNG supply and distribution, making LNG accessible to regions that were previously unserved.

3. LNG Bunkering

The use of LNG as a marine fuel has gained traction, with dedicated LNG bunkering facilities being developed at major ports worldwide. LNG bunkering helps reduce greenhouse gas emissions from shipping, making it a cleaner alternative to traditional marine fuels.

4. Cryogenic Technology Improvements

Advances in cryogenic technology have significantly improved the efficiency and safety of LNG storage and transportation. New materials and insulation techniques are enhancing the performance of LNG tanks and pipelines, reducing boil-off rates and minimizing energy losses.

5. Carbon Capture and Storage (CCS) Integration

Integrating CCS technology with LNG operations allows for the capture and storage of CO2 emissions produced during gas processing. This innovation helps the LNG industry meet stringent environmental regulations and reduce its carbon footprint.

6. Enhanced Heat Exchanger Designs

Heat exchangers are critical components in the LNG liquefaction process. Recent innovations in their design have led to more efficient heat transfer, reducing energy consumption and operational costs. These new designs also improve the reliability and lifespan of the equipment.

7. Digitalization and Automation

The adoption of digital technologies and automation in LNG operations is improving efficiency and safety. Predictive maintenance, real-time monitoring, and automated controls help optimize processes, reduce downtime, and enhance decision-making.

8. Hybrid Power Solutions

Combining LNG with renewable energy sources, such as wind and solar, to create hybrid power solutions is an emerging trend. These systems provide a stable and reliable energy supply while reducing greenhouse gas emissions and reliance on fossil fuels.

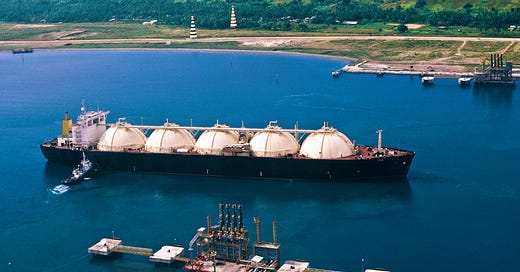

9. Advanced LNG Carriers

The design and construction of LNG carriers have seen significant advancements. Modern carriers are equipped with efficient propulsion systems and enhanced containment technologies, reducing fuel consumption and emissions during transportation.

10. Methane Emissions Reduction Technologies

Innovations aimed at reducing methane emissions during LNG production and transport are crucial for the industry. Technologies such as advanced leak detection, repair systems, and low-emission valves are helping to minimize methane release, a potent greenhouse gas.

These top 10 innovations are not only driving the LNG industry forward but also playing a pivotal role in the global transition to cleaner energy. As the industry continues to evolve, these advancements will help meet the growing demand for LNG while addressing environmental concerns and improving operational efficiency.